Updating

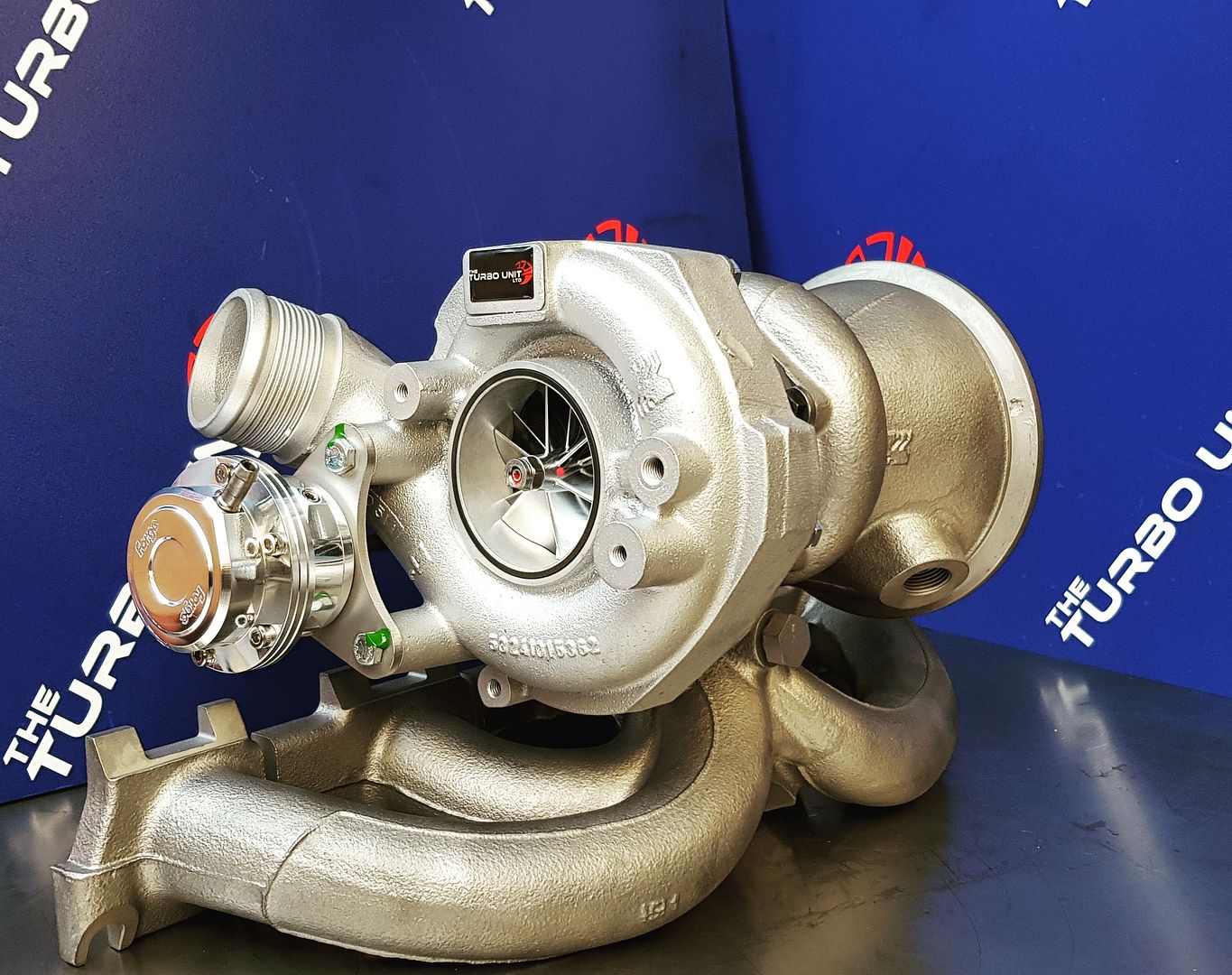

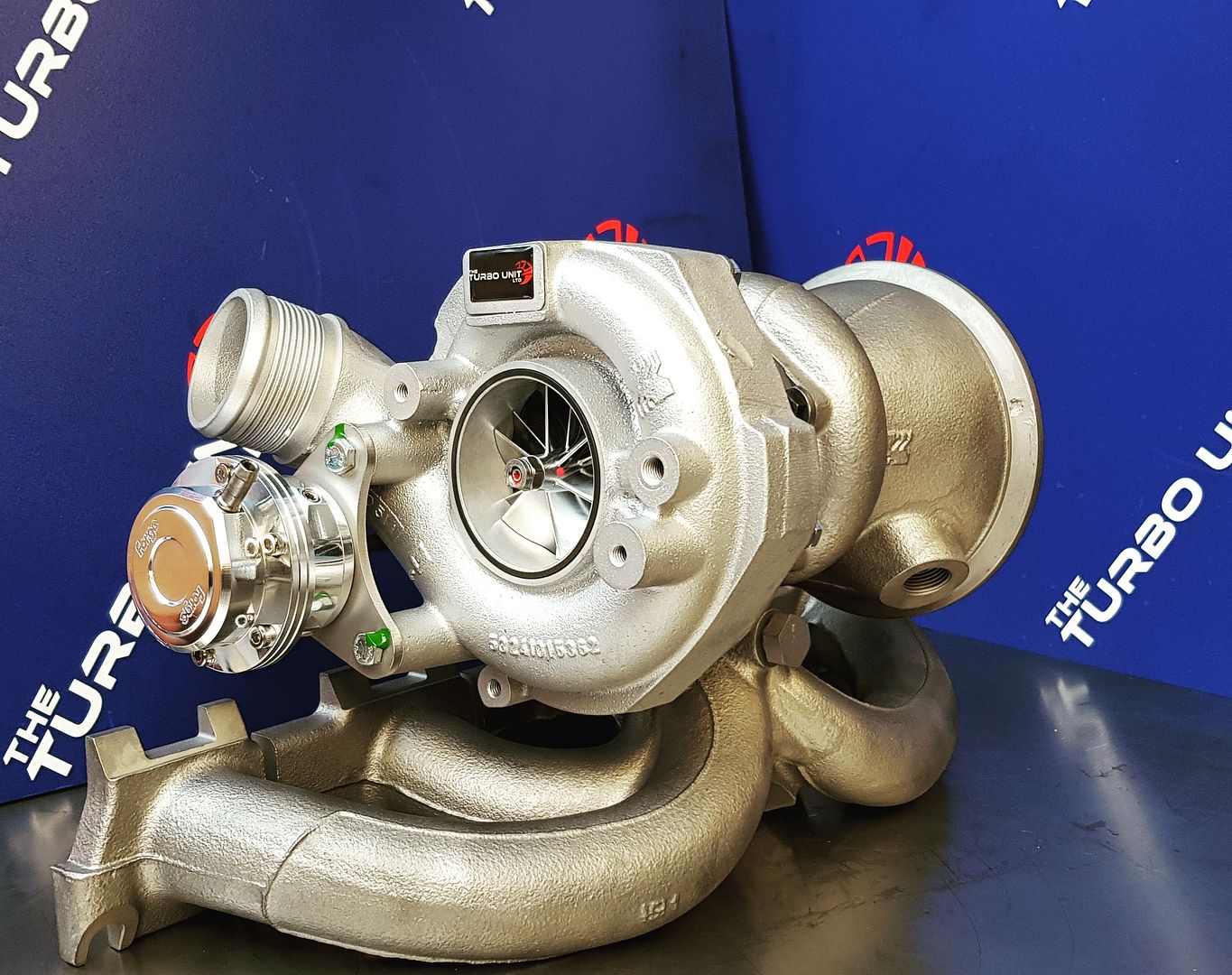

We designed our unique TTU hybrid for the RS3 8p 8v pfl and TT RS 8j

Our TTU hybrid was developed for a all round unit for road use.

back ground on our design.

When we first stripped the k16 turbocharger it was clear the turbine wheel was the chocking point for this unit. So we got to work on measuring the inducer and exducer blades, Once we had found the correct size turbine/shaft we had some decisions to make regarding cut back blades.

Now the science behind cut back blades, is miss lead by many turbocharger companies. We hear comments like it is for low down response and to produce less back pressure in most cases this is just simply not true. Facts are cut back blades create better flow higher up in the rev range due to its weight loss, but destroys your low down output. Now trying to get best of both worlds is really involved, unless you have time to keep trying to create the perfect angle it can become impossible to master.

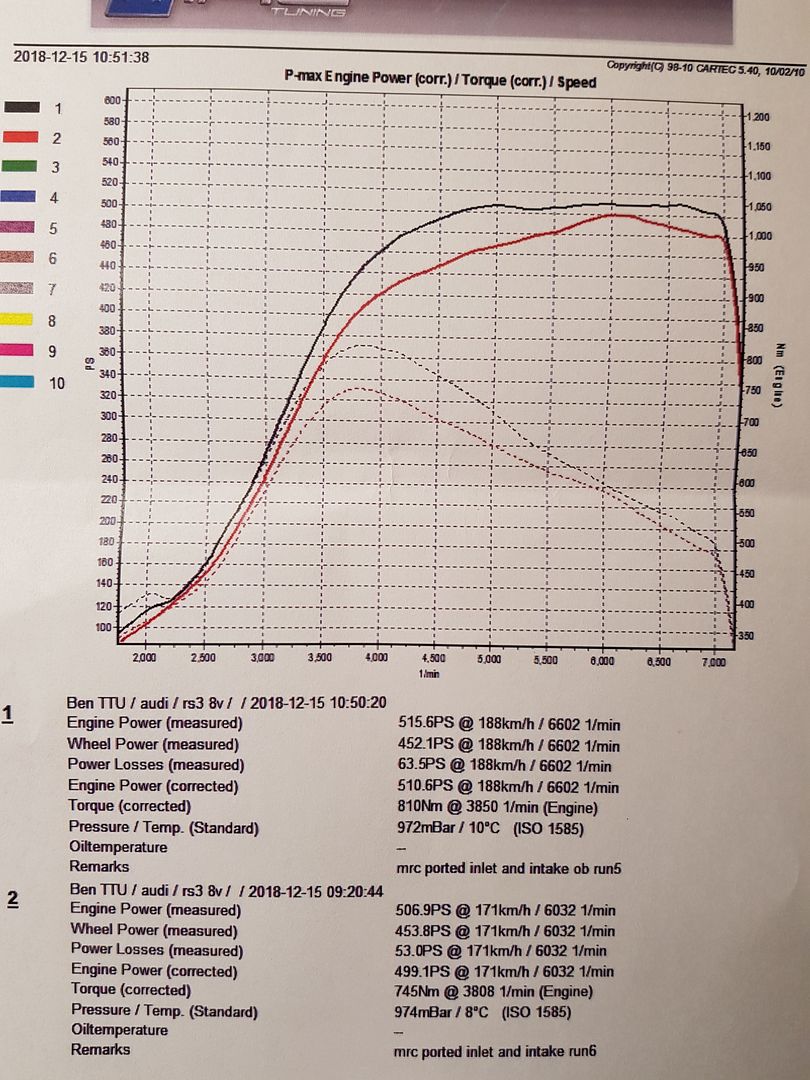

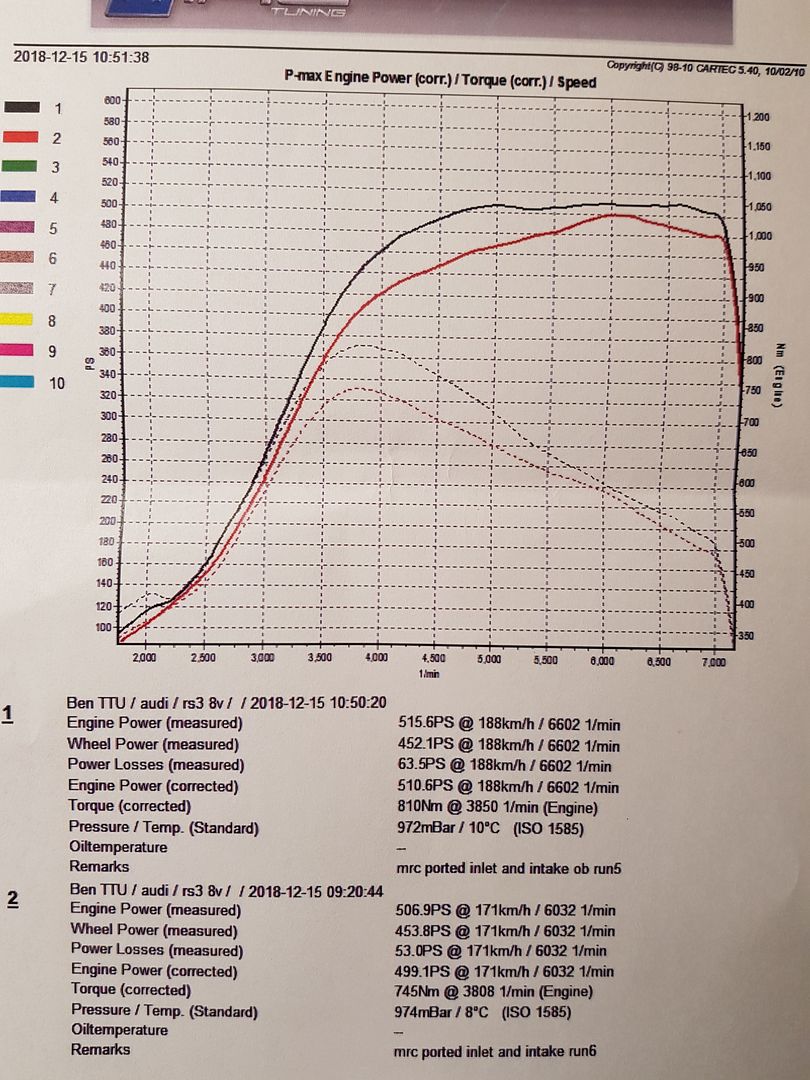

As the 2.5tfsi engine was born from Diesel power designs, we felt that torque is where we should be at. So we completely left the turbine wheel alone, giving us that amazing low down response and producing 280ps @ 3k rpm.

Billet compressor wheel.

We are not going to lie we actually took a sneak peak at other hybrids on the market to see if we could learn from there said designs.

The facts where we was not going to attempt to fit the billet wheel others are using, they are far to large and would effect our low down spool and cause the car to choke or even turbo stall. We went for a slightly larger wheel over stock with extended tip technology for maximum durability.

Actuator

We did some testing with the OEM actuator, we found it could only hold enough boost to produce 448hp, when we fitted a one bar forge actuator the turbo came alive and produced an extra 40hp top end.

thrust bearing

the so called Motorsports up rated thrust bearing that every man and his turbo dog uses. The thrust bearing as standard is a 360 degree bearing, the uprated version is from a diesel and is stronger due to being a 7 thrust pad not a 5 pad like in the k16, this design is done due to diesels running higher boost levels from stock. Some companies do use a fully closed 360 degree bearing but we do not use them, and feel they have no benefit over the 7 pad design.

high speed balancing

Our core is balanced to 110k rpm @ 0.5gs with 8 bar of air pressure, the unit reaches these speeds in just under 4.6 seconds

I will not sit here and tell you we balance our units UPTO 250k rpm, as this is just silly and is impossible to run a k16 or even a k04 to them speeds, it would simply destroy its self.

We are now designing a plug and play hybrid that is ball race from the EFR range.

Edited by BenTTU, 07 April 2019 - 11:10 AM.

Sign In

Sign In Create Account

Create Account

Back to top

Back to top Quote

Quote MultiQuote

MultiQuote